Organised collaboration of the research community and industrial stakeholders can fuel internationally competitive development projects which, exploiting research excellence, reflect on existing market demand. This is the long-term objective of the eight university-industry cooperation centres launched with EU and domestic funding in 2017. Representatives of the ongoing projects were reporting on their readiness level to an expert panel invited by the NRDI Office.

József Pálinkás, President of the NRDI Office delivered an opening presentation on the outcome of the interim reviews at a conference focusing on the “BME model as a common sense in sustainable university-industry cooperation”.

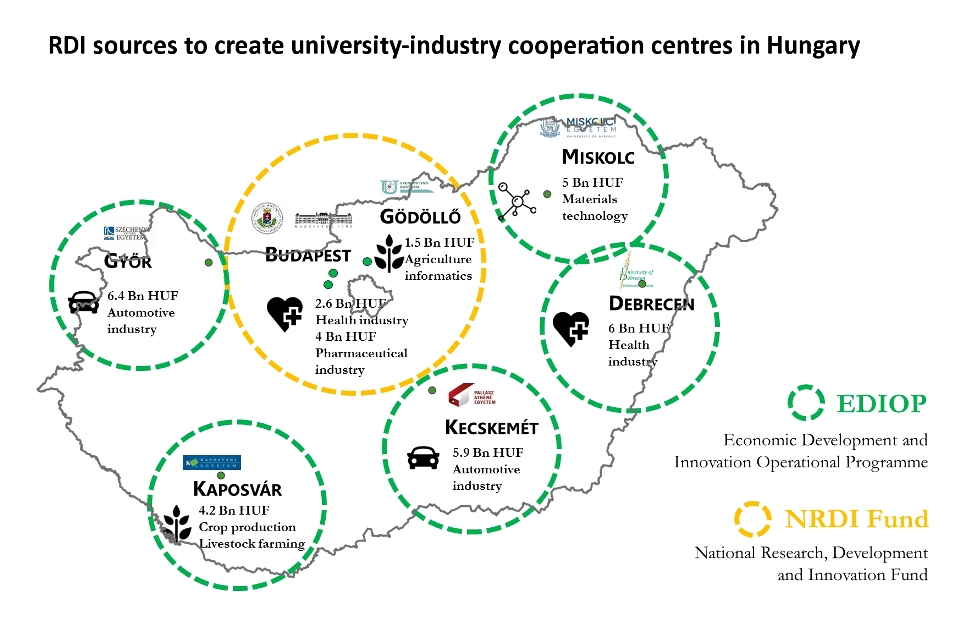

The EU-financed call of “Research infrastructure development of Higher Education and Industry Cooperation Centres (GINOP-2.3.4-15)” was available only for projects implemented in less developed regions, while applicants from the Central Hungary region were offered a similar call (FIEK_16) announced by the NRDI Office from domestic sources. These schemes aim to optimise links between university and industrial R&D within a new institutional approach, and speed up the transfer of scientific results into practice. This enables education to get closer to industrial needs and also contribute to the vocational training of industrial staff. Under the two calls, five new R&D centres were launched in Győr, Kaposvár, Miskolc, Kecskemét and Debrecen with EU funding of HUF 26.8 billion altogether (EUR 86.5 million), while further three consortia in Central Hungary received HUF 8 billion (over EUR 25.5 million) from domestic sources.

In terms of their objectives, based on the expertise of participating consortium members, the newly launched centres are specialised in developments in the automotive, agricultural, molecular biology, materials technology, plant cultivation, info-communications, pharmaceutical and energy industries, so as to give further impetus to R&D activities of university-industry partnerships already existing in these regions.

As an organisation being politically responsible for the entire spectrum of RDI call schemes and their financing agency in part, the NRDI Office pays particular attention to the implementation process of publicly funded RDI projects, including the ones funded under the two calls for FIEK consortia. Upon initiation of the NRDI Office along with the Managing Authority of the GINOP/EDIOP funds, professional reports of all beneficiaries funded under the two calls financed from EU sources or the NRDI Fund were reviewed at the same time, to have their activities and achievements assessed by the same expert panel against a uniform set of criteria. While making such reviews, the expert panel observed, among others aspects of a project, implementation timing, contribution to strengthening links between industry and higher education, and strategies for long-term sustainability. Reporting presented in person is a new and complex element under a professional approach within the monitoring system of publicly funded projects, that complements traditional documents-based methods of professional and financial reports, and site visits to check conformity with rules.

Presentations were requested to follow assessment criteria fixed beforehand:

- implementing organisational and operational conditions

- professional and financial proceedings of the project

- scheduled timing of project implementation and any discrepancies

- results of the project so far achieved

- tasks scheduled for the next project period

- further cooperation and development options identified as a result of the FIEK centre

- strategic visions to found long-term sustainability

- problems and risks identified in the course of implementation

As an outcome of the presentations and further inquiries made by the panel members, the following snapshots are made on current FIEK programmes:

The three projects in Central Hungary are running as scheduled. Financial expenditures are in line with the professional output, project plans and remaining tasks comply with the project objectives. Long-term marketing and sustainability of the projects are clearly seen. Emerging risks, if any, are properly managed, so they mean no threats for the implementation. In the case of the Eötvös Loránd University (ELTE), the risk caused by the delayed investment due to vis major is managed by launching a temporary lab. In the case of the Budapest University of Technology and Economics (BME), the process of public procurements is behind the schedule but it does not hinder project implementation. In the case of the Szent István University, also a delayed infrastructure investment that requires special attention and its consequences should be carefully examined in the next professional report.

Rural projects show various readiness levels, the expert panel also warn about certain deficiencies and risks. In the cases of the Széchenyi István University, the Kaposvár University and the Miskolc University, these do not hinder projects implementation, but some identified risks do need remedy.

In the cases of the Debrecen University and the Neumann János University, several serious risks have been identified. In the first one, delay in forming the organisation and financing significant extra costs caused by earlier under-budgeting, while in the latter long arrears of implementation (project was launched 8 months later than scheduled) and deficient communication between consortium members set back investments. The expert panel calls for increased level of control on these projects.

Results achieved in the BME FIEK project so far:

- While forming their FIEK model, consortium members created the common structure for university-industry projects, the operation and management of which is adjusted, on the principle of mutual benefits, to the given business environment. Since the FIEK centre was launched, several companies inquired about collaboration options.

- Besides FIEK units at launch, organised for the purpose of individual projects, an Industry 4.0 Technology Hub was also established to offer development for SMEs. Enterprises can learn the most advanced technologies by using demonstration tools, to be able to increase their efficiency and competitiveness. Apart from individual projects, this is also a way for the FIEK centre to build and strengthen its links with the industry. This ensures interaction kept with companies even after a project is completed, thus contributes to sustainable business relations.

- A successful test flight was completed with the electronic aircraft developed in the framework of the project. Energy storage and transformation methods, development of the motor and transmission system have been realised in full compliance with very strict inflight security demands.

- The technological model of continual pharmaceutical production has been completed, the continual purification process of active ingredients has also been elaborated.

- Plans are done to interconnect the FIEK labs and further R&D capacities of the university into a joint network. This network means preparing for the world of 5G and enables new 5G applications and services to be developed and tested.

Results achieved in the ELTE FIEK project so far:

- Even in the first year of operation, the management was able to build further collaborations and thus attract further potential of investments, applying the methods of existing research projects as a model for the purpose of investigating other diseases.

- Awareness-raising trainings and information days are regularly held for research centres not only to get familiar with each others’ work but to learn ways of patenting, marketing and research activities with commercial approach.

- Experts specialised in this sector were invited to make a business plan for the FIEK centre that seems solid and sustainable in the current environment.

- Upon international advancement in the field of biotechnology in recent months, the profiles for bioinformatics and image analytics have been reinforced.

Results achieved in Sthe zent István University (SZIE) AgIT FIEK project so far:

Four sub-programmes – LAB; ISOBUS; DPS; DATA – being implemented.

- ISOBUS research group is now capable of doing ISO 11783 conformity examinations, the instrument developed can be applied to read and save the full data traffic of any CAN based communication and, as a virtual tractor, to address the operational computer and read out its data structure.

- At the Hannover Agritechnica exhibition, the university negotiated with representatives of AEF (Agricultural Electronics Foundation) which coordinates ISOBUS-related developments, who agreed that SZIE now possesses human resources and infrastructure suitable for ISOBUS conformity examinations that AEF stations are capable of and entitled for.

- DPS research group, collaborating with ASSECO and AXIAL has made a regulator algorithm for the Digital Production System, carried out measurements on arable lands for the soil-to-plant nutrient uptake model, the mathematical algorithm of which has also been made.

Results achieved in the Széchenyi István University FIEK project in its first year:

For the development of the Packaging Research Laboratory, procurement for a walk-in climate chamber, an incline impact test equipment and equipment to examine the compression of large size flexible packaging were made. Then the accreditation of the laboratory has been renewed and extended to include examinations to be made with these instruments, and also an international US accreditation has been cleared for the same. In the first phase of the project, the number of lab users has increased with nearly 30 new partners and, through organising international symposia and professional benchmarking, the lab starts its way to get internationalised.

The lab is accredited by the MSZ EN ISO/IEC 17025:2005 standard. The Packaging Research Laboratory is member of IAPRI (International Association of Packaging Research Institutes); accredited by ISTA (International Safe Transit Association); has more than 200 industrial partners from 20 countries; has trans-border cooperation with other accredited labs from the Czech Republic, Austria, Slovakia and Poland.

Major specialisations: tests of transport packaging, type examinations of packaging for hazardous goods; quality control test of packaging materials; R&D projects; consultancy and training; tests for the automotive industry.

Virtual Reality Systems: a VR-Learning research group was launched to look into the possibilities of VR applied in education. In 3D spaces prepared within the FIEK project students show a 30% efficiency increase, measured on a sample of 400 students.

Within the FIEK project, tutorial and laboratory spaces were made in MaxWhere environment which are also used by other schools. These spaces are on display at MaxWhere.com