Currently, the vast majority of scrap tyres are recycled to create crumb rubber which is primarily used for the coating of sports fields and playgrounds and for energy purposes, such as in the cement industry. Another form of high-volume application could be the so-called “rubber bitumen” but this technology is still in the experimental phase in Hungary. It would be another evident recycling opportunity to use crumb rubber as an additive in various natural rubber compounds in manufacturing processes, but the volume that can be utilised this way is limited: the amount of even the finest crumb rubber fractions (under 1 mm grain size) may not exceed 10 weight percent in any compound. Thus, new methods and application areas must be identified for recycling scrap rubber.

This is exactly in the focus of the project funded in the Researchers’ Thematic Applications Programme financed from the NRDI Fund: researchers at the BME Department of Polymer Engineering assume that the microwave treatment of crumb rubber allows for the cleavage of the chemical (carbon-sulphur and sulphur-sulphur) bonds in its cross-linking structure. This enables the creation of mobile molecules that can attach to the matrix molecules to provide the necessary strength for the boundary formed between them. In this process, adding carbon black to rubber can promote efficient heating and the uniform distribution of heat in the material, even in the case of apolar rubbers.

A major challenge of the research team is to explore how the type of the rubber used as raw material in the experiments, i.e. the additives and fillers inside, influence the effectiveness of the microwave treatment. Their hope is that the innovative devulcanisation method will allow crumb rubber to be used in larger quantities in the rubber industry, while further experiments are needed to decide to what extent the amount of fresh natural rubber can be replaced in the manufacturing process. “It is our priority to provide useful recommendations to future industrial users of the method as to what types of rubber products (summer or winter tyres, motor-car or heavy duty truck tyres) are the most suitable for the microwave devulcanisation process” says Tamás Bárány, head of department and project leader.

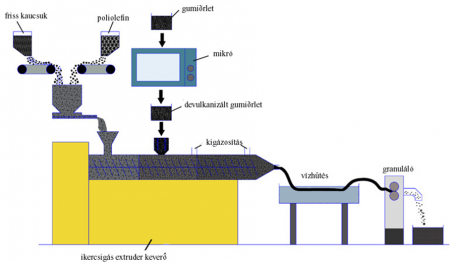

Another goal of the project is to create a product with high added value, more specifically a thermoplastic elastomer which can be reprocessed multiple times through repeated smelting. The researchers plan to produce the thermoplastic elastomer – by partly or entirely replacing fresh natural rubber with microwave treated crumb rubber – with a new continuous manufacturing process while reaching optimal material properties (stretchability, elasticity).

As a practical result, the research project is expected to lay the foundations of and develop procedures which can be easily and quickly introduced to industrial processes and have the potential for mass production, with particular regard to the continuous production of thermoplastic elastomers.

|

The researchers’ previous relevant funded projects:

- 2006-2009: Development of environmental friendly, self-reinforced polymer composite – F 60505 (HUF 4.865 million)

- 2009-2012: Development of a novel polymer composite of advanced recyclability for large series production – K 75117 (HUF 9.538 million)

- 2012-2015: Rubber/crystallizable thermoplastic oligomers compounds with improved processability and properties – K 100294 (HUF 19.910 million)

---------------------------------------------------------

Funded project: K 115949

Upcycling of crumb rubber after microwave devulcanization in rubber and thermoplastic elastomer formulations

Duration: September 2015 – August 2018

Project leader: Tamás Bárány, associate professor, head of the Department of Polymer Engineering, Budapest University of Technology and Economics

Amount of funding: HUF 32.388 million